Prefabricated Components Structure

Steel prefabricated components refer to assembly parts that are produced and processed to a certain extent in the factory, with an independent structural system, and can be directly transported to the construction site for installation. Common steel structure prefabricated components include steel beams, steel columns, steel bridge beams, steel structure floor slabs, etc.

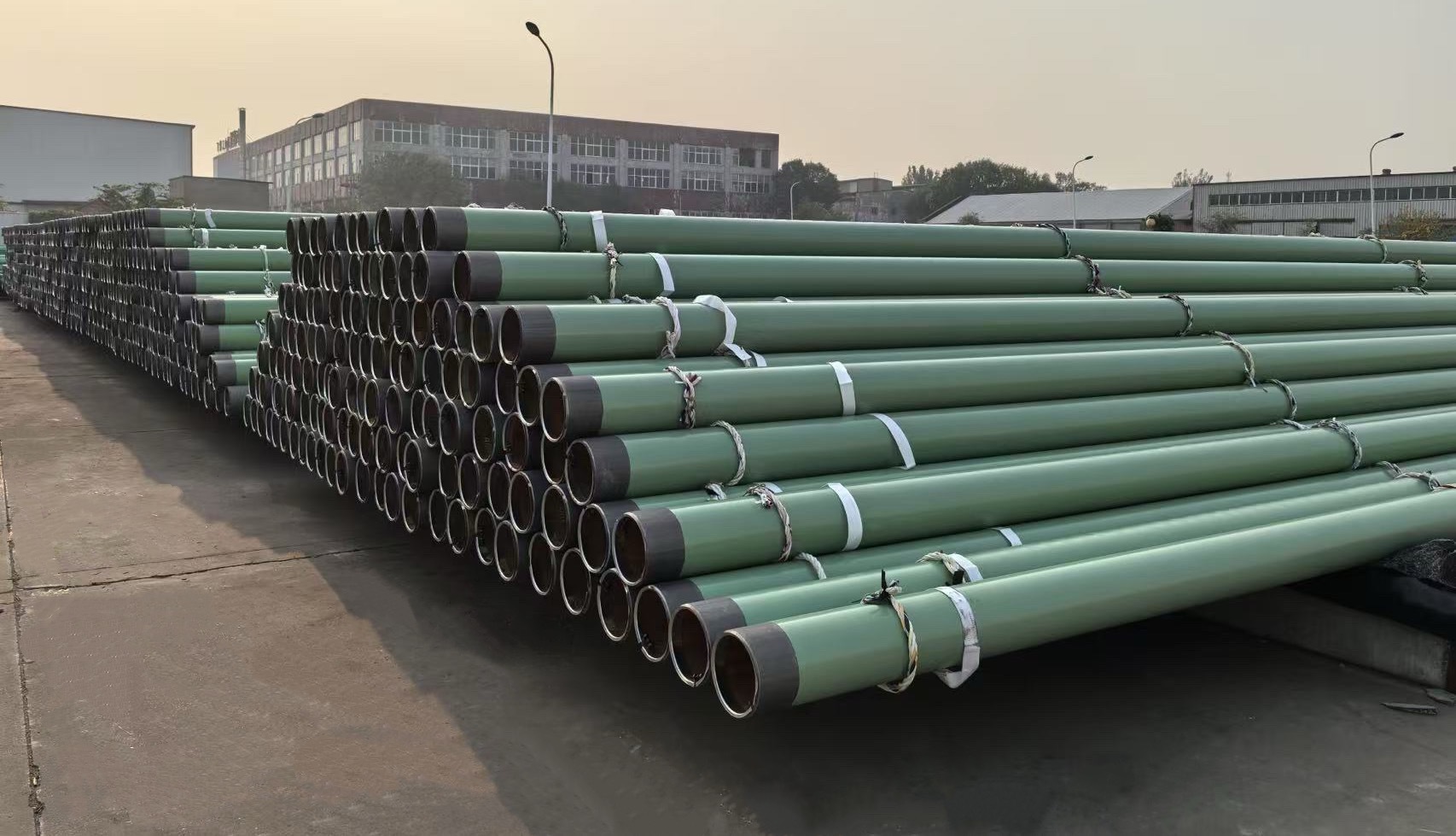

According to their application and form, they can be divided into frame prefabricated parts, plate prefabricated parts, steel pipe prefabricated parts, etc. The advantages of this structure include high strength, light weight, good overall stiffness, and strong resistance to deformation. It is particularly suitable for constructing large-span, ultra-high, and ultra-heavy buildings. After prefabrication in the factory, it can greatly save installation and welding work on the project site. Steel prefabricated components can be used for various types of mountain bridges, railway bridges, highway bridges, urban light rail bridges, substations, substations, ship structures, elevators, offshore platform structures, etc

Pressure Bearing Construction Structure

The main load-bearing components of a building are divided into horizontal and vertical walls, which mainly bear horizontal and vertical loads. Column - a component that mainly bears vertical loads, used to support floor or roof loads, mainly divided into frame columns, component columns, etc. Beam - a horizontal load-bearing component used to support the load on floor or roof panels, mainly divided into square or cross shaped steel structures. The load-bearing structure places great emphasis on the quality of welding in production, and generally requires full fusion welding with very precise requirements for straightness and torsion. When it comes to complex welding component testing, in addition to conventional MT and UT testing, special testing molds need to be made to ensure that the dimensions of each small component are consistent with the drawing requirements.

The basic components of a bridge include the upper structure, lower structure, support system, and ancillary facilities. The substructure refers to the part of a bridge located below the support, also known as the supporting structure, which includes piers, abutments, and the foundation of piers. The adjacent two span bridge is located in the middle of the bridge, and the basic concept of the box girder structure is that all upper structures become integral hollow beams. When the main load passes through any position on the bridge, all parts of the hollow beam (ribs, top plate, and bottom plate) participate in the force as a whole. The lower structure is usually made of steel plates, steel pipes, angle steels, H-beams, and other parts, which are welded together through components and ultimately connected on-site by welding or bolts.

Xinyue can provide customers with design analysis, drawing splitting, steel production, welding and forming work, etc.

Coal Mine Construction Structure

During the construction process of coal mines, a large amount of steel pipes and supporting steel structures are required to build the main shaft (vertical shaft), excavate the main roadway, divide the mining area, and establish the working face. The steel structure of coal mines is usually used for mine support, which has high requirements for the performance of steel and the quality of welding.

In the past few years, Xinyue has provided drawing splitting, material supply, welding finished products, pre installation, and on-site guidance for multiple coal mine projects both domestically and internationally, accumulating rich experience in the supply of coal mine steel structures.